Aggregate Industry Solutions

Rising demand for aggregate materials due to population growth and infrastructure investment requires operations to enhance productivity and profitability. Whether you mine, crush, screen, blend, or convey it, you rely on equipment to move material throughout your facility—performing under rigorous conditions, including high shock loads and extreme weather, while keeping everyone safe.

With decades of experience in the aggregate industry and working with bulk material handling applications, we understand the challenges you face.

From inventing the concept of shaft mounting a gear reducer to over a century of mounted bearing leadership, the team at Dodge® is committed to providing you with tailored solutions for your operations to maximize uptime, enhance on-site safety, and save money.

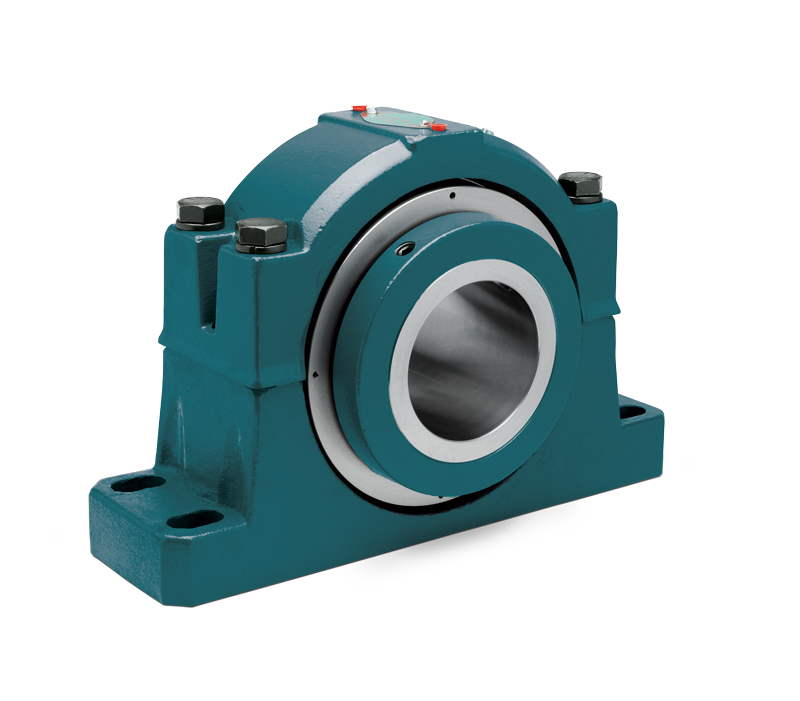

TAF mounted tapered roller bearing

Frac sand bucket elevator

A frac sand bucket elevator saw an annual savings of $445,380 by replacing existing split bearings with Dodge TAF mounted tapered roller bearings, eliminating the opportunity for contamination during installation and outlasting the competition with over eight times the life.

-1-1.png?width=800&height=650&name=Intelli-Lube_RemoteMount-BeamClamp-2pt_TypeEXL+TypeE-XTRA+250cc+Sensor(Gen2)-1-1.png)

OPTIFY™ Intelli-Lube™

Frac sand slurry pump

A frac sand producer saved $1,731,440 annually by implementing Dodge OPTIFY Intelli-Lube automatic lubricators to their slurry pumps. This upgrade saved hundreds of hours of manual greasing labor, prevented pump failures in a high-contamination environment, and mitigated costly downtime.

Motorized Torque-Arm (MTA)

Granite quarry belt conveyor

Through implementing MTA, the quarry eliminated routine maintenance tasks and improved application reliability—reducing unplanned downtime and resulting in an annual savings of $67,030.